Reebok Factory Visit: Behind The Scenes With The OG Pump Fury

As Reebok gear up to celebrate the 20th anniversary of the Insta Pump Fury, Sneaker Freaker was recently invited behind the bamboo curtain to document production of the classic OG Fury colourway. Flying from Hong Kong into Fuzhou, I was feeling… well and truly pumped. In more than a decade of covering the sneaker industry, this was indeed a rare assignment. Watching the very thing that you love so much being made right in front of your eyes is a surreal experience.

In broader terms, it’s also a revealing glimpse into the mysterious nature of the mega industrial ecosystem that is Southern China. On more than one occasion I had to stop and think twice about everything we take for granted in the West. Forget about the notion that sneakers are not handmade – well over 100 workers touch each and every Pump Fury before they hit the street. Each pair of hands is responsible for a singular part of the process, ranging from screenprinting, embroidery and sewing to glueing sole units and heat welding Pump bladders. There’s no laces on the Fury of course, but there is someone at the end of the line who stuffs the shoes with padding and adds the Reebok Reserve hangtags, just before they’re wrapped in tissue paper and boxed for delivery. Passing QC (quality control) is no joke – the inflatable valves are leak-tested at least three times on every shoe. Like I said, watching all of this makes you think, which is a good thing.

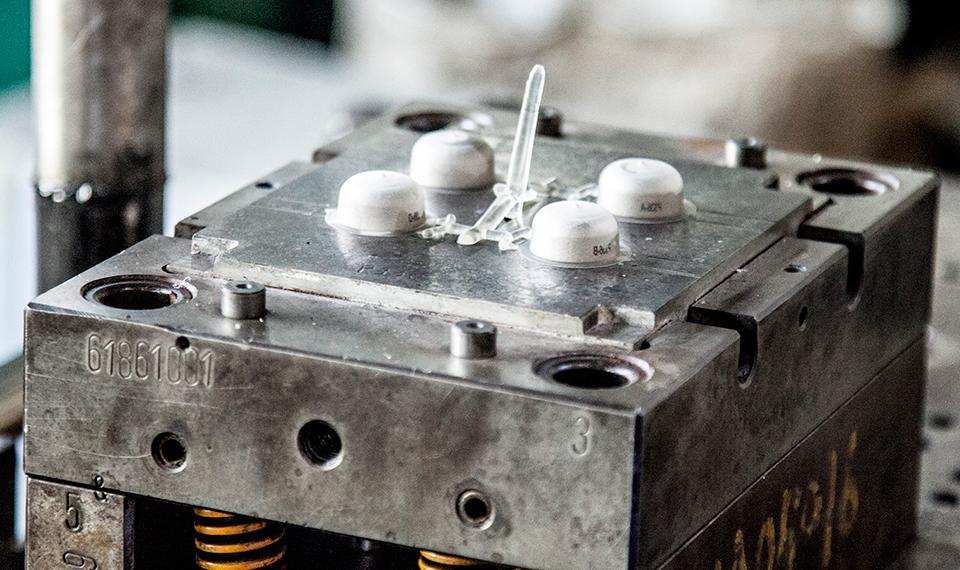

As the striking red, citron yellow and black combo progressed from being a handful of polyester and rubber pieces into a three dimensional Pump Fury, it was heartwarming to know that Reebok have committed extraordinary resources to making the Fury exactly as they were made in the mid-90s. From the midsole pattern to the overall shape, this extends to reopening the precise OG moulds, as well as recommissioning obsolete factory equipment that had been dormant for some time.

To their immense credit, Reebok were also very, very cool about letting me loose in the ‘FuLu’ factory. They had every right to be sensitive to bourgeois gripes about 'manufacturing in the Far East', but it’s clear they also have the confidence that comes from knowing that the factories they use to make Reebok shoes are safe, clean and legitimately managed, in every sense. Credit also to FuLu's management, it was impossible not to be impressed by the conditions as the workers went about their business with a minimum of fuss. From A-to-B, it was truly a marvel of efficiency and organisational smarts. There’s way more to this than what we have time for here, so look out for a full length report in Issue 30 of Sneaker Freaker. Thanks to all at Reebok for the invitation and the warm hospitality… Life is short, play hard!