New Balance Introduce New 3D-Printed TripleCell Platform

The beloved is getting its most contemporary makeover yet as have brought 3D printing to the beloved runner.

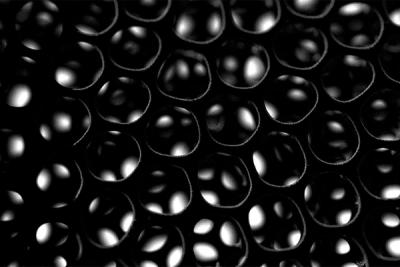

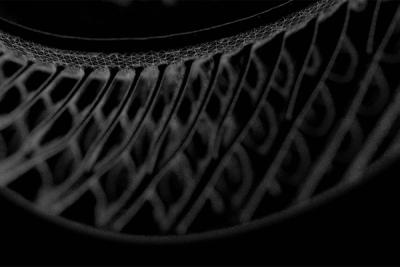

Dubbed the 990 Sport TripleCell, the new kicks reimagine the classic design for the modern runner and are highlighted by a brand new 3D-printed heel component – created in conjunction with Massachusetts-based Formlabs – that's made of a durable, high-rebound photopolymer resin. Couple that unique cushioning with a breathable mono mesh upper and you have a 990 that's 10% lighter than the .

'TripleCell will deliver the industry’s pinnacle expression of data to design with seamless transitions between variable properties underfoot,' says Katherine Petrecca, New Balance General Manager, Innovation Design Studio. 'This new, cutting edge, digitally manufactured technology is now scaling exclusively within New Balance factories in the U.S. further establishing us as a leader in 3D printing and domestic manufacturing. Formlabs has beenan integral partner to bring this to life. We’re really going to be able to disrupt the industry not only in performance, but also in athlete customization and speed to market.'

'3D printing is changing how companies approach manufacturing, with this announcementNew Balance is pioneering localized manufacturing,' adds Dávid Lakatos, Chief Product Officer of Formlabs. 'By eliminating the dependence on moulds and direct printing for both prototyping and production, their team shifts from months to hours in the development and production cycles. We’re moving towards a world where design cycles are closing in on the whim of the consumer and it’s exciting to be on the frontlines of this with New Balance.'

You can grab a pair of the American-made kicks now while supplies last.