Nike Considered Sneakers

You gotta hand it to the guys at Beaverton. So many new projects, so many new ideas, it’s almost a full-time occupation keeping track of all of them. This latest effort is called Considered, and it has been cleverly designed to create minimal impact. The shoes are constructed from as few individual components as possible, have almost no lining, use recycled rubber, hemp laces and Vege-tan leather and can be easily disassembled.All things Considered, we think they’ve done an outstanding job!

The final result appears defiantly un-Nike, but at this point we are interested in ideas over aesthetics. Putting out a project tagged with a ‘green’ reputation like this is a political gamble for a megalopolis like Nike, who are an easy and predictable target for activists. We’re not here to defend their track record on workers' rights and environmental policy, but we do think they should be applauded for their efforts in this instance. At least Nike have had the balls to ask some hard questions that generally get swept under the carpet. Namely, how do companies alter their work practices to produce consumer goods with minimal waste, use less raw materials and eliminate toxic byproducts like solvents and PVC, not to mention making them eminently recyclable? We caught up with the Designer, Andreas Harlow for a chat about this unusual looking project... is this a glimpse into the future of all Nike products?

Hey Andreas, how’s Beaverton?

It’s good actually. We’re pretty busy. As you can imagine we’re working hard, but it’s a nice time of year.

We know that you’re originally from New Zealand and studied in Wellington, how did you end up at Nike USA designing shoes?

Good question... I’ll give you the short story. I originally came over to the US to snowboard and I decided to stay. I got into footwear by accident and did that for a few years before Nike gave me a call and here I am.

That was brief!

Oh you want more than that?

Well I know a lot of our readers are very interested in shoe design as a career...

OK, I can tell you about that. I went to a school for general product design, there’s not really a shoe design school as such... and then

I got into different products, architecture a little bit, furniture, lighting, computer products... But, to me, I’m a pretty outdoorsy kind of guy and it wasn’t really grabbing me the way I’d hoped so that led me to sporting goods. So I followed my passion to some degree...

Well that’s always a good thing to do.

Tell us about Considered in your own words, it’s obviously a project that you are passionate about. How do you describe it?

Well you’ve probably seen the website and seen a bit of press, but my description in a few short words keeps three things in mind: innovation, sport culture and the environment. I guess the environ-ment is a new addition to that equation, but those three things cover it pretty well. Innovation at Nike has been about making people jump higher and run faster. We still do that pretty well I’d say, but this environmental issue is something that is becoming more important.

Have you found people to be cynical about a massive company like Nike putting out a product tagged as ‘environment friendly’? What’s the reaction been like?

Well, when you do something new there’s always gonna be haters, doubters who are mistrustful. We’ve encountered a few of those. But on the flipside of that, I’d say no-one’s perfect, we’re trying to do the right thing with the knowledge that we have, so you can look at it two ways. People say to me, ‘How can you work there when Nike does this and that?’ And I say, ‘Well you can stand there and whine about it and form a picket line, or you get involved and try and change something for the better.’ And that’s my personal perspective on it.

I would totally agree, why attack someone for doing something good! Considered raises some interesting questions about the way we consume products and also the way things are made. Was it a hard project to get through the Nike system?

It was definitely a challenge, I’ll say that. (laughs) I think a few people didn’t quite understand what we were doing but now that we have some product it has helped that situation. Also, there was a lot of support and a lot of people that were working on this project for the last ten years, to my knowledge have been adding ingredients to this solution. So we had good support at the same time.

Really? So this has taken ten years to get the product to market?

Yeah, well I mean, it depends on how you look at it. If you look way, way back at some of the sustainability work being done at Nike, it would go back a long way. The guys in The Kitchen, Mike Aveni being one, have been working on this for some time. There were a bunch of raw ingredients lying around, we’ve augmented it, added to it and made a cake out of it.

Who else helped bake the cake with you?

The core group that I work with was Richard Clarke who is Creative Director in Active Life, Jesse Leyva was also involved in the marketing, Brad Long who is a developer and works with the factory to get the shoes made, Steven Ploem in Thailand was also instrumental and not to forget the guys at The Kitchen, Tobie Hatfield and Eric Avar, they did a lot of work on the FREE aspect to it.

That was probably the first thing I noticed in Generation 2 of Considered, the new FREE sole unit. Why did you use that sole?

In Gen 1 we were talking about the craftsmanship of yesterday with the technology of today. That led us to think about natural things. So when we went down to The Kitchen and talked to them, the work on FREE was well underway and it just seemed like a good fit. It helped the shoe to flex, to seem more like a part of your foot. So it feels good and it’s better for you. We like to say this shoe is good for the environment but also good for your feet.

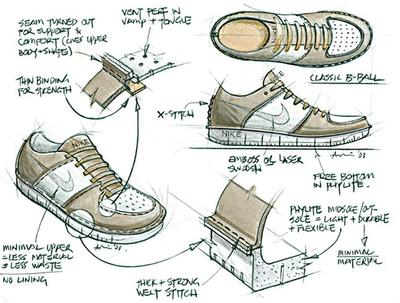

The fact you have used as few steps as possible in manufacturing, there’s no lining, the stitching is on the outside of the shoe, there’s no reinforcements internally... there’s a lot of constraints in terms of design. Did that make it difficult to control the final outcome?

Yeah that’s right, your question shows design thinking at work. I totally agree, we tried to look at it really more like the glass is half-full than half-empty. For example, when you do a normal athletic shoe, there are a huge amount of things available to you and that can drive the end result a certain way. With this project we just tried to be really honest about the things we could and couldn’t use and let that drive the result. That’s one of the reasons the shoes look and feel unique.

Speaking of which, the overall look has a rustic, almost woody feel to it. If you’re making something like this with an environmental edge to it, does the product have to look like that to convey the message as well?

The short answer is no, they don’t have to... but when we started Considered we made a conscious decision to make the shoes in a way that people could understand them. You may see in the future that our new shoes take a completely new aesthetic because we’ve chosen a new mix of ingredients to attack that problem. With Gen 1 and 2 we took a more natural approach and we think it makes sense, and people who are looking for that kind of product would understand it.

I agree totally. I suppose I was hypothesising if you made the shoes silver and red would anyone understand the project? The texture and the colour implies the nature of the shoe.

You hit the nail on the head. But it’s not to say it couldn’t go other places and we’ve been working on that for the last year or so. There’s a limit as to how far you can push people before they drop off and we didn't want this to be a cerebral, self-congratulatory effort, we wanted to get shoes on feet and also do the right thing.

Why did you choose to make these shoes in Thailand?

There were a lot of reasons, the primary one would be the ability of people in those factories to execute the product. The second major one was the materials were available locally so we went with ecologically sound leathers from a local tannery which was a major focus.

I often get enquiries from people who like sneakers but have political views opposed to leather... did you ever consider using a synthetic upper?

Yeah we did, we’ve been working on that for a little while, and I empathise with anyone who doesn’t wear leather products, but these shoes are not for them. Hopefully in the near future we will have something for them. It’s a complicated issue. From a pure design point of view, leather really is, especially with this project, the best material to make this shoe from, if you take away the emotional aspect. It’s long lasting, it has good handle, it breathes well, it doesn’t require lining or oil to make it per se. So there’s a bunch of factors.

That raises an interesting point. Which is, how do you assess products in a holistic way environmentally? In case of leather versus synthetic material, the by-products of synthetics aren’t great. Then you throw in transport pollution, energy usage, recycling potential and so on, and you’ve got a very complex equation.

That’s right, especially when you start adding glues in there, they become quite hard to biodegrade and recycle. It’s a pretty complicated issue and I’ve gotta say we spent a lot of time as a team strategy-planning about what we were and weren’t gonna do, which materials we would use and so on. And I think to some degree we are still in a learning process on that because some stuff you just have to try to find out, there’s really not a lot of information about it.

The project also has a recycling element. Will it be like Mayfly, for example, where you post them back to head office?

I wish! That didn’t happen with this project unfortunately.

The recycling issue is one that I think our sustainability group has been championing. So, in all honesty, my expertise and my sphere of influence has been limited to the design and production of the shoe. They’re the experts on the other side of the coin.

There’s also an aspect of Considered which uses recycled materials as well isn’t there?

Yeah, correct. In Gen 1 we used Nike Grind on the rubber outsole as an example. In Gen 2 we got rid of the outsole altogether. So, again, we’re just reducing the amount of material we use as a result.

The idea with the bottom of Gen 2 is that the whole piece could be cut off as a single polymer unit and can be ground up and made into another product.

Have you calculated how much energy it takes to make a Considered shoe, as opposed to a normal sneaker?

I don't have that info. Our sustainability group have done a bunch of research on the prototyping and the actual production. Hopefully we will have some hard facts soon.

How do you see Considered evolving? Will it take on a life of its own at Nike?

That’s a good question, it kind of has. To give you some idea, we are in the process of designing Gen 5 right now so it has grown a little bit and it is having an impact on other products at Nike. To gauge that impact you’ll have to look in a lot of different places.

Does that mean we will see existing Nike shoes re-considered or re-engineered?

Yes. It’s definitely one of our strategic goals and we have a policy on that, it’s just a question of when. One of the other projects I am working on will take the notions of Considered and, how shall I put this, in a different material palette and for a different consumer...

I don’t want to give too much away but that’s a big one and we hope that will be a bit more mass market.

You mentioned Gen 3 and 4 before, have you finished sampling on those ranges?

Yes we have. I think people will be pleasantly surprised at the different approach we have taken. I think it is exciting looking at the same problems in different ways, in the same way that a song can be remixed as a dub or a reggae version or whatever. The same thing applies with Considered, although it’s not so much a stylistic thing, it’s more about solving problems in a different way. Projects like this take quite a bit of trial and error so it keeps things fresh, we learn things along the way and we try and incorporate them as we go along, so in that sense it keeps everything fun.

Thanks Andreas and good luck with your projects.

According to the Nike Sustainability Group, Considered creates 63% less waste than a comparable Nike light hiking shoe, creates 33% less waste than conventional production, reduces solvent use by 80% compared with typical Nike products, primarily uses materials found close to the factory, requires less energy to construct, uses vegetable dyes and leather tanned using recycled wastewater. And in case you’re wondering, 95.6% of Nike shoes now use water-based solvents.