Behind The Nike Pro Turbospeed: Matt Nordstrom Interview

TurboSpeed racing suits are part of Australian sporting folklore, with Cathy Freeman famously wearing a hooded one-piece on her way to 400M gold at the Sydney Olympics. Matt Nordstrom is one of the designers behind these radical track suits, and he recently visited the home of the 2000 Games to help open Nike's latest Innovation pop-up shop and to shed some light on the science behind the Pro TurboSpeed, Nike's fastest track uniform yet.

Any Olympics aficionado knows the early version of the Turbo-suit from Cathy Freeman's epic run in Sydney. How did the project originate?

Project Swift started in 1998, in preparation for the 2000 event. This here is the suit we built for Cathy Freeman. Not the exact suit she wore, but it is of the same era with the same design.

Cathy's suit looks like something from the 70s compared to the new model.

Yeah, it's funny. For over 12 years now we've definitely been continually evolving Project Swift and have been applying it to a lot of different sports. I've designed time-trial suits for Lance Armstrong that he's worn in the Tour de France, all of which have been proven in aerodynamic studies to reduce drag. Leading into this summer, we basically gave ourselves a mission to completely rethink how we were doing it. We set out to do something extreme. After a thousand hours in the wind tunnel and incorporating insights from some of the fastest athletes in the world, we've got the fastest suit we've ever made.

Sounds easy!

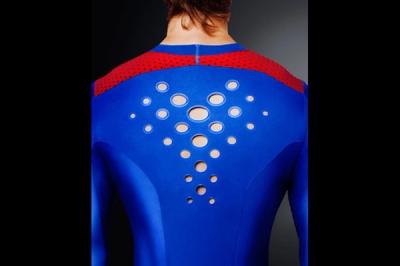

Consider the movement of a track sprinter; different parts of the body are all moving at different speeds. Athletes commonly move in excess of 32 kilometres per hour. When they are moving at that speed, some parts of the body, like the lower leg, are actually moving closer to 75 kilometres per hour. So that is easily within the realm of aerodynamic influence. In fact at those speeds, we've found that there's basically three realms worth exploring to help the athlete go faster. One is ‘zoned aerodynamics' and is very similar to how a golf ball's texture helps it go faster and farther. We use similar technology on the surface of the suit to reduce the cumulative aerodynamic drag coming off the athlete.

So did you work with Olympic athletes day-to-day?

Absolutely. The athlete is very much at the centre of the whole process. They help us clarify what our goals are from a design point of view and what we're trying to do, especially in products like this where you're dealing with the fastest athletes in the world. What's kind of unique about that whole space is that the athletes are defining the status quo. They're breaking limits, they're breaking boundaries and that's what we're trying to do with our product as well; to help them do that.

So how does it work?

Okay, so here's the deal. A perfectly smooth golf ball of the same dimension would punch a big hole in the air that leaves a really wide wake behind it. What the dimpled texture does is it creates a slightly turbulent boundary layer or surface layer against the ball. And that slightly turbulent layer, for whatever reason, stays attached to the ball longer before it peels off. So the result is that the textured ball actually has a much narrower wake behind it. What you're seeing there is a reduction in aerodynamic drag. This is not theoretical by the way. This has been proven since the '30s.

So a totally smooth suit would actually be slower?

Absolutely. The suit we have is absolutely faster than if the entire suit were fully smooth. The textures on this suit are the fastest texture for that part of the body moving at sprint speeds. It's a very counter-intuitive principle actually because rougher is indeed faster. It was proven by the leading sports aerodynamicist in the world, who's been working with us on this since 1998. The principle of zone aerodynamics is something we were using for Cathy Freeman's suit as well. The big difference is that the texture was inherent to the knit structure, so when we wanted to move from one texture to the next we actually had to put a seam break in. Four years ago we started really playing around with different ways of imparting different surface architectures on things. We also started playing around with different ways of doing prints to get different textures. What we developed was this process that we call Nike AeroSwift, which allows us to print those three-dimensional textures that are informed by the wind tunnel research.

So those dots or dimples are actually a print?Crazy, they look like perforations.

Yeah it's a print. Because we're printing that texture on the fabric, we have much greater control over the size of that dot, the spacing, the rhythm of the texture and we can also make changes from one part of the body to the other.

The Turbo-suit obviously looks like a sprinter's uniform. Do you need to customise it for individual athletes? They're not a normal shape for a human being are they?

No, we did extensive anthropometric data gathering on a lot of different sprinters and we started to see what their body profile is like. First of all they're extremely fit and they're definitely statistical outliers. They are at the top of their game. They're excellent at what they do. Do you know who David Oliver is?

David Oliver, the hurdler?

He is huge. He's got deltoids the size of my head! So he is built in a very unique way. So there's a unique fit scheme for the suit but then we size it out appropriately and we have not needed to do any custom-fit work on any of this stuff.

Are you nervous that one of the suits may split open and we'll have a really unexpected Olympic moment?

No, not really. (laughs) We go through a lot of trouble to make sure that we're thinking of everything and the quality control is there. You'll notice some of these seams are ultrasonically bonded and reinforced from behind. One thing we realised in Project Swift was that seams themselves cause drag. So what you'll find is, wherever possible, we've taken the seams and we've moved them to the back of the athlete where they're hidden from the wind. They're in the shadow of the wind and wherever we can't do that, we use a much flatter construction technique!

Is this suit only available for that real top-level sort of performer, or can anyone buy this Turbo-suit in a Nike store?I can't imagine zipping down the shops for a pint of milk in it.

Well in the case of the innovation of ‘zoned aerodynamics', you need to be going about 18 miles an hour to really start appreciating the benefit of a reduced aerodynamic drag. So the specific innovation doesn't really translate for the everyday athlete. But there are so many things that we learnt from it about how to build apparel.

++

Thanks to Matt for his time explaining the Turbo-suit!