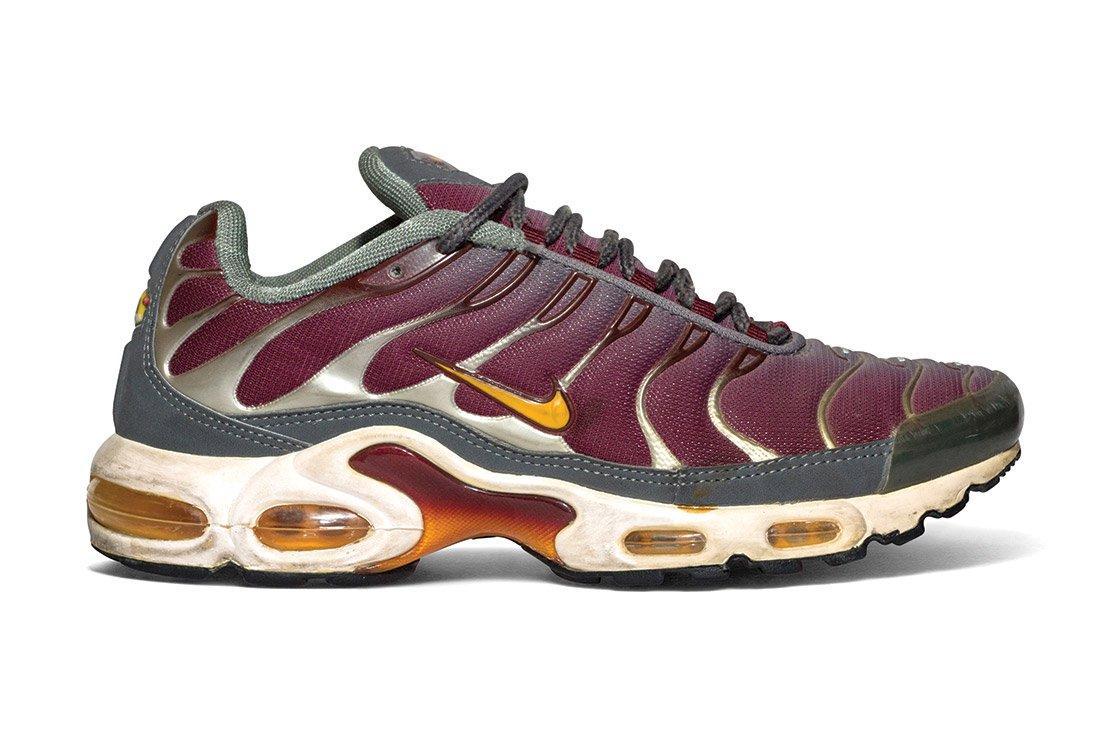

Material Matters: Tuned Air And The Air Max Plus

There’s no denying that the Nike Air Max Plus (aka the TN) is a cultural phenomenon. Adopted by subcultural tribes the world over, its hyper-aggressive form is as loved by those who rock them as it’s reviled by the general public. With such a dedicated cult following, there must be something special built into that Tuned Air sole.

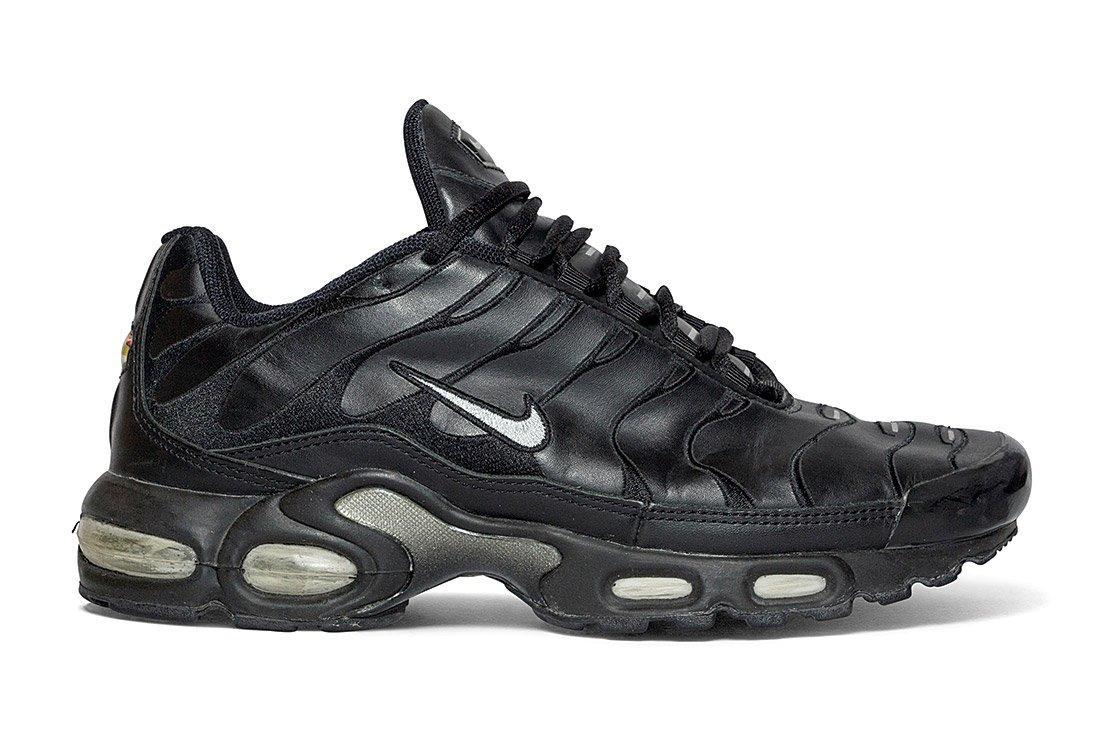

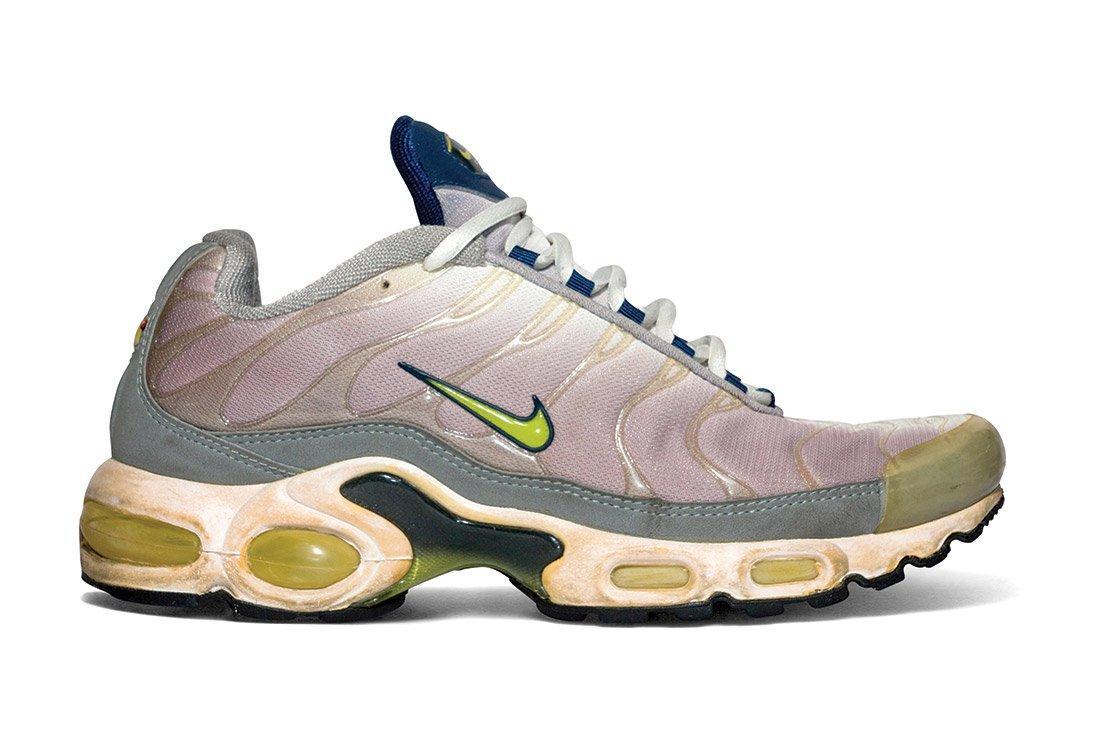

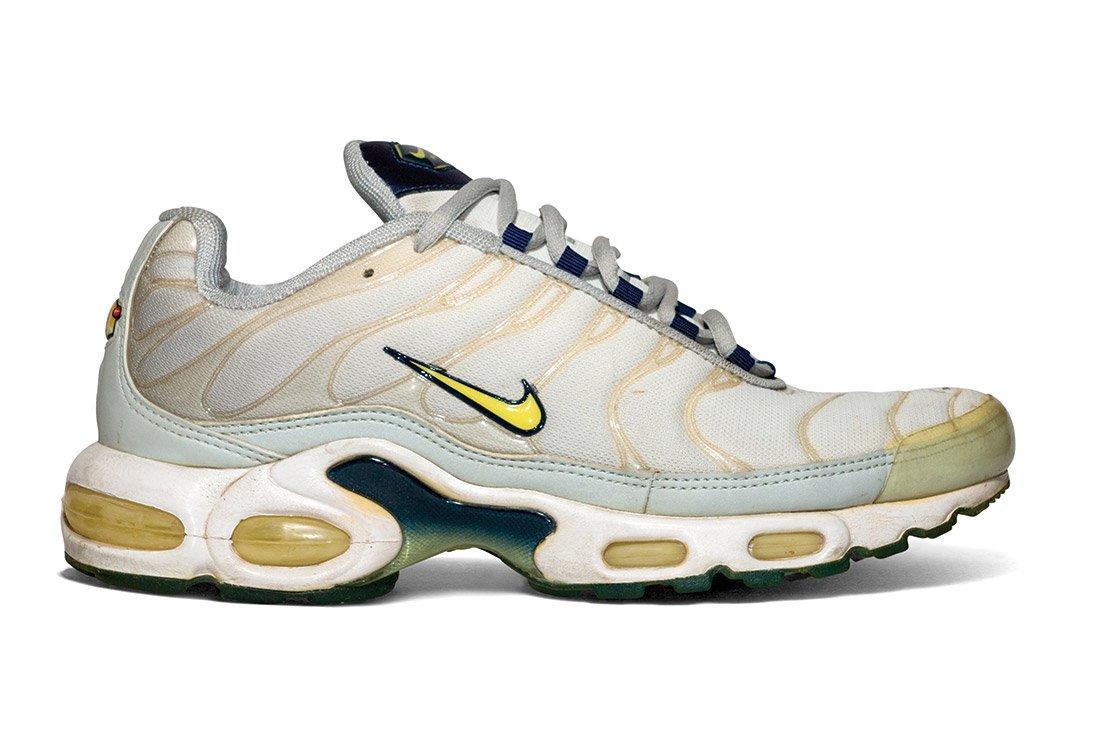

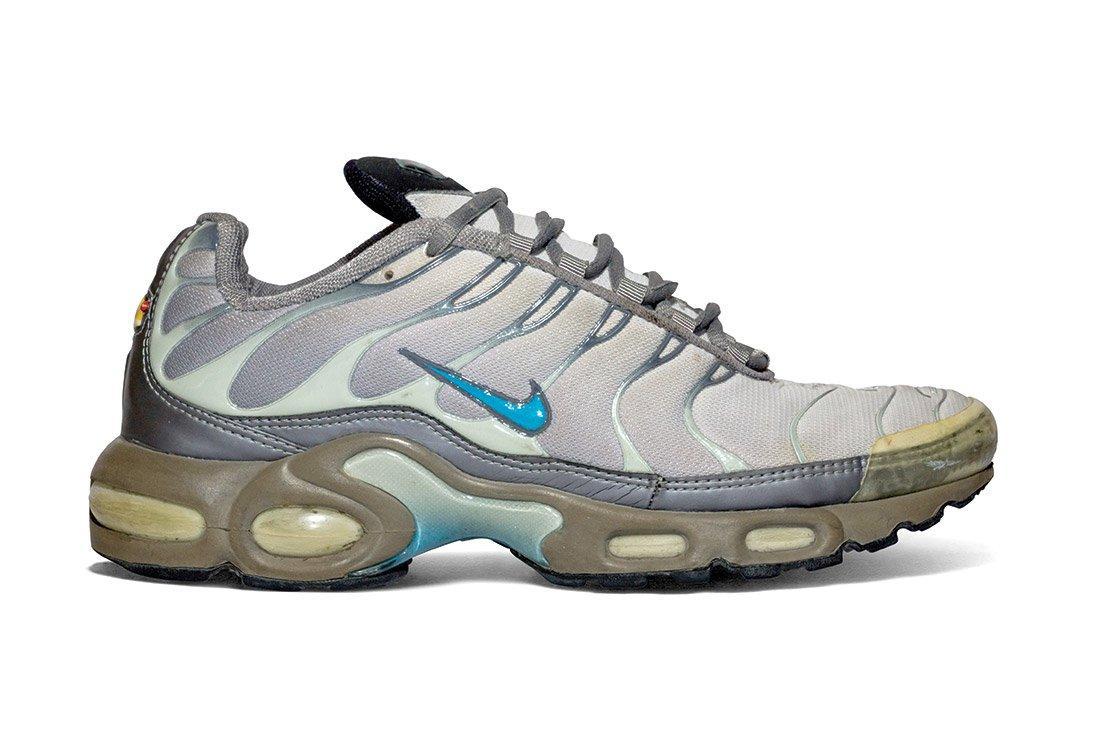

Photo by Phil Aylen

The Air Max Plus bubble